-

Tortilla Production Line

-

Fruit Processing Line

-

Fruit Puree Production Line

-

Fish Chili Sauce

-

Jam Paste Sauce Processing Line

-

Fruit Juice Production Line

-

Fruit Vegetable Processing Line

-

Color Sorter Machine

-

UHT Sterilizer Machine

-

Tomato Paste Processing Line

-

Mango Processing Line

-

Citrus Processing Plant

-

Commercial Tortilla Machine

-

Lavash Bread Maker Machine

-

Apple Processing Line

Adjustable Lavash Bread Making Machine

Contact me for free samples and coupons.

Whatsapp:0086 18588475571

Wechat: 0086 18588475571

Skype: sales10@aixton.com

If you have any concern, we provide 24-hour online help.

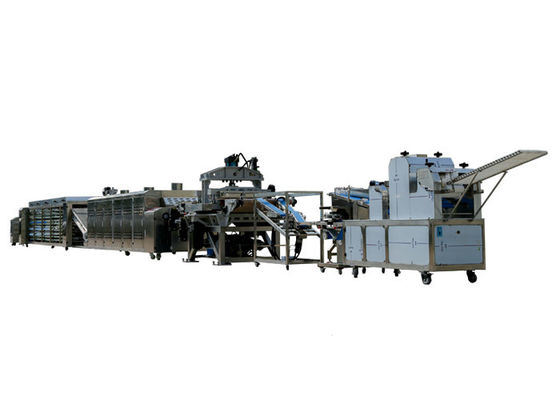

x| Usage | Lavash Making | Power | 30 Kw |

|---|---|---|---|

| Dimension | 25m X 5.5m X 2.0m | Weight | 9000 Kg |

| Gas Injiection | 8-14 M³/h | Thickness Of Pancake | Min 0.5mm |

| Material | 304 Stainless Steel | Advantage | Fully Automatic And High Efficiency |

| Function | Lavash Bread Production Line | ||

| Highlight | Adjustable Lavash Bread Making Machine,Sanitary Lavash Bread Making Machine,7000pcs/h Lavash Bread Automatic Line |

||

Multifunctional Safe 30kw Armenian Bread Production Line with High Efficiency

1. Product description

Automatic lavash bread machine and press tortilla machine.

| Diameter | Capacity |

| 8 inch | 14000 pcs/h |

| 12 inch | 7000 pcs/h |

2. Features:

1) Multifunctional Function & available for making various of food, including sticky products or thin skin juicy products.

2) Made of 304 stainless steel, consistent with the International food safety standards, easy for operating, cleaning, assembling and repairing.

3) Wide usage. It can be used for home, factory, store, supermarket, school, dining hall, hotel, hospital etc. Can make delicious.

4) You can enjoy 12 months warranty and longlife guidance and aftersale services for our customers, you don't need to worry about anything.

![]()

3. Process

![]()

1) After two rolling machine, the dough is thinned from thick.

![]()

![]()

2) Arrive to piling part, the dough is piled.

![]()

![]()

3) Next is horizontal rolling part, get out the space gap in pilling produce. After that, the dough sheet is pressed in two pressor to make it to become thinner and flatter.

![]()

![]()

4) The widor make the dough wider and thinner to prepare for next cuting step.

![]()

![]()

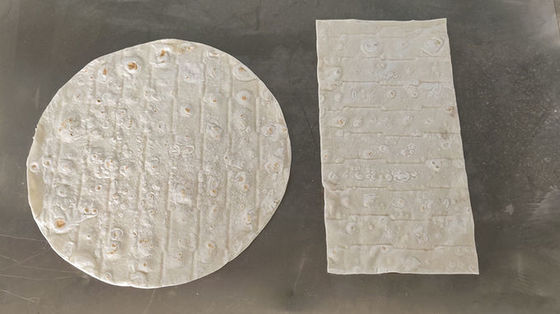

5) This machine can cut the dough into round or rectangle shape. The changing of knife can change the pancake shape. The round shape model has there type.

![]()

![]()

6) The rest of dough goes into the barrel to collect and second use.

![]()

![]()

7) Baking and cooling

![]()

![]()