-

Tortilla Production Line

-

Fruit Processing Line

-

Fruit Puree Production Line

-

Jam Paste Sauce Processing Line

-

Fruit Juice Production Line

-

Fruit Vegetable Processing Line

-

Color Sorter Machine

-

UHT Sterilizer Machine

-

Automatic Packing Machine

-

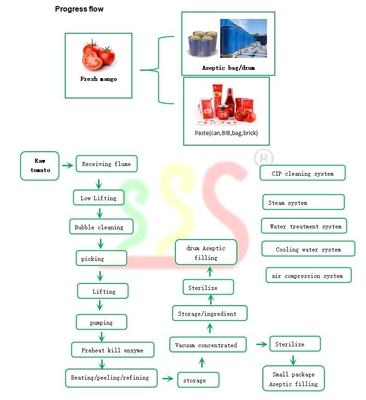

Tomato Paste Processing Line

-

Mango Processing Line

-

Citrus Processing Plant

-

Commercial Tortilla Machine

-

Lavash Bread Maker Machine

-

Apple Processing Line

Fresh Tomato Ketchup Jam Paste Sauce Processing Line

Contact me for free samples and coupons.

Whatsapp:0086 18588475571

Wechat: 0086 18588475571

Skype: sales10@aixton.com

If you have any concern, we provide 24-hour online help.

x| Item | Fast Food Tomato Ketchup Processing Line Jam Paste Sauce Processing Line | Input | Fresh Tomato |

|---|---|---|---|

| Output | Tomato Paste | Capacity | 1-100t/h |

| Feature | Turnkey Project | Product Packing | Bag/bottle/BIB/glass |

| Highlight | Tomato Ketchup Processing Line,100t/h Tomato Ketchup Production Line,Fresh Jam Paste Sauce Processing Line |

||

Fast Food Tomato Ketchup Processing Line Jam Paste Sauce Processing Line

Fast Food Tomato Ketchup Processing Line Jam Paste Sauce Processing Line consists of tomato pretreatment unit, pulp making,allocation system, packing and control system

![]()

| Vacuum Concentrator Evaporator |

Ø Rated capacity: 400L/h; Ø The special equipment for jam concentration fully absorbs Italian technology, suitable for the characteristics of heat-sensitive and high-viscosity materials of fruit juice, and can be continuously concentrated under vacuum conditions; Ø The main unit is composed of multiple sets of heaters, multiple sets of evaporation chambers, water ring vacuum units, multi-stage water pumps, water tanks, circulating pumps, discharge pumps, concentration refractometers and operating consoles; Ø Rated evaporation capacity: 400kg/h (water evaporation meter); Ø Falling film circulating type, multi-effect evaporation (multi-stage structure); Ø Vacuum degree: 90KPa; Ø Evaporation temperature: 48-78℃; Ø Heating temperature: 65-80℃; Ø The feed concentration is 4.5-10.5Brix, Ø Export finished product concentration is 28-30Brix; Ø Circulating cooling water volume: 100 tons/h (inlet water temperature 32℃); Ø Water supply: 5 tons/h (inlet water temperature 32℃); Ø Condensate tank liquid level automatic control; Ø Steam valve group: globe valve, pressure reducing valve, regulating valve, steam trap, filter, etc. Ø Japan Alto Online Sugar Meter Ø The part in contact with the material is SUS304 stainless steel Ø Condenser and operating platform are made of carbon steel and are treated with anti-rust coating; Ø Contains 2 sets of circulating volume control pneumatic valves, 2 sets of variable frequency speed regulating starch pumps, 1 set of cooling multi-stage water pumps, 4 sets of circulating pumps, 2 sets of discharge pneumatic F-type control valves, and a set of other auxiliary accessories; Ø 1 set of temperature controller; Ø 1 set of vacuum sensor Ø 3 sets of automatic liquid level control (differential pressure transmission - negative pressure type) Ø Installed capacity: 200KW Ø Dimensions: about 3500*250*500mm (L*W*H) Ø The cabinet of the electrical control cabinet is made of SUS304 stainless steel; Ø Dimensions: 900*500*1800 (L*W*H); Ø Implement system material transmission, liquid level control, concentration control, signal conversion and other controls; Ø Electronic components use the same brands as Omron, Mitsubishi and Siemens; |