-

Tortilla Production Line

-

Fruit Processing Line

-

Fruit Puree Production Line

-

Fish Chili Sauce

-

Jam Paste Sauce Processing Line

-

Fruit Juice Production Line

-

Fruit Vegetable Processing Line

-

Color Sorter Machine

-

UHT Sterilizer Machine

-

Tomato Paste Processing Line

-

Mango Processing Line

-

Citrus Processing Plant

-

Commercial Tortilla Machine

-

Lavash Bread Maker Machine

-

Apple Processing Line

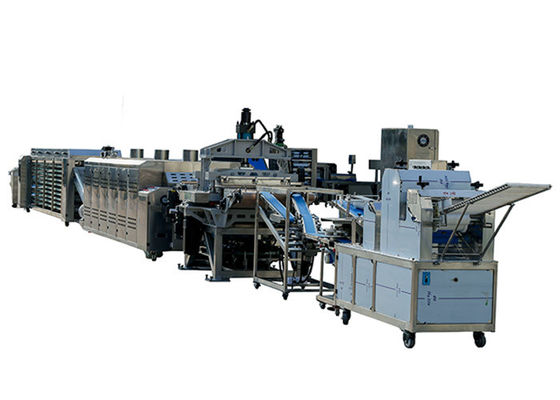

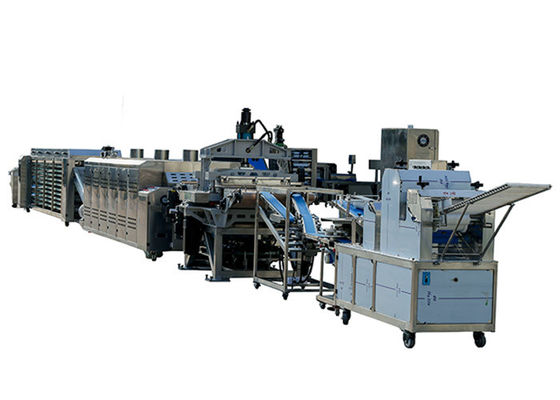

12 Inch Commercial Tortilla Making Machine

Contact me for free samples and coupons.

Whatsapp:0086 18588475571

Wechat: 0086 18588475571

Skype: sales10@aixton.com

If you have any concern, we provide 24-hour online help.

x| Condition | New | Warranty | 1year |

|---|---|---|---|

| Voltage | 380V | Power | 50~60HZ 1.1KW |

| Dimension(L*W*H) | 17000*1200*1800mm | Weight | 4800kg |

| Key Selling Points | High Productivity | Tortilla Diameter | 20cm--45cm |

| Air Consumption | 3 M ³ /min | Application Fields | Snack Food Factory, Bakery |

| Highlight | 12 Inch Commercial Tortilla Making Machine,45cm Commercial Tortilla Making Machine,High Productivity Flour Tortilla Making Machine |

||

fhot sale 8 inch 10 inch 12 inch 18 inch tortilla production machine

Product Description

1. The screw is made of alloy (38 CrMoAL) by nitriding, high strength and wear. And it has good self-cleaning ability, and does not require discharging or cleaning the barrel and propeller, when frying or changing materials; The segment screw is applicable for more kinds of materials and products. At the same time, it is easy to change and reduce the replacement cost.

2. It adopts a speed control converter on the feeding system, extrusion system and cutting system, which can control the speed with more powerful drive, stable stroke and lower consumption.

3. Automatic lubrication system in the transmission, it can reduce power consumption and extend the service life.

4. The heat sink is enlarged on the moving part for forced cooling effect, and it ensures the safe operation of the extruder.

5. Water cooled circulation barrel, raw material not only for corn / rice, also for high viscosity wheat flour / starch. Various Temperature Humidity and Extrusion Ratio, Fully Expanded and Semi Expanded as different type of products.

6. Hanging mold and knife steat can increase the speed of mold and knife changing.

| Capacity | 200-3600pcs/hour |

| Material | 304 Stainlesss Steel |

| Power | 16KW |

| Application | Food Industry |

| diameter of product | 20cm--45cm |

![]()

![]()

Company Profile

Our senior engineers have more than 20 years' professional experience in the field. Taking advantage of advanced technology and innovative design conception as well as rich experience in food processing machinery, we have been providing the highest level equipment for customers from all over the world. Our main markets are Russia, UK, USA, Brazil, New Zealand, Southeast Asia, Australia and so on.

Packing & Delivery

2. Only plastic film nude packing with wooden pallet.

3. We can supply package and certificate.

4. Delivery, train, as requested by customers.

Exhibition & Customers

![]()

After Sales Service

Pre-sale service

* Help and consulting support.

* An example of testing support.

* View our factory.

After-sales service

* Training to install the machine, training to work with the machine.

* Engineers are available to service machinery overseas.