All Products

-

Tortilla Production Line

-

Fruit Processing Line

-

Fruit Puree Production Line

-

Fish Chili Sauce

-

Jam Paste Sauce Processing Line

-

Fruit Juice Production Line

-

Fruit Vegetable Processing Line

-

Color Sorter Machine

-

UHT Sterilizer Machine

-

Tomato Paste Processing Line

-

Mango Processing Line

-

Citrus Processing Plant

-

Commercial Tortilla Machine

-

Lavash Bread Maker Machine

-

Apple Processing Line

Automatic Lavash Production Line Leavened Thin Flatbread Making

Product Details

| Material | 304 Stainless Steel | Processing Types | Automatic Line |

|---|---|---|---|

| After Warranty Service | Online Support | Name | Lavash Making |

| Power | 16kw | Thickness Of Pancake | Minimun 0.5mm |

| Highlight | Automatic Lavash Processing Equipment,Lavash Automated Production Line,Leavened Lavash Production Line |

||

Product Description

Automatic Armenian Lavash production line leavened thin Flatbread making Machine

MAIN FEATURES1: Automatic conveying of dough ball to haydraulic heating forming chember.

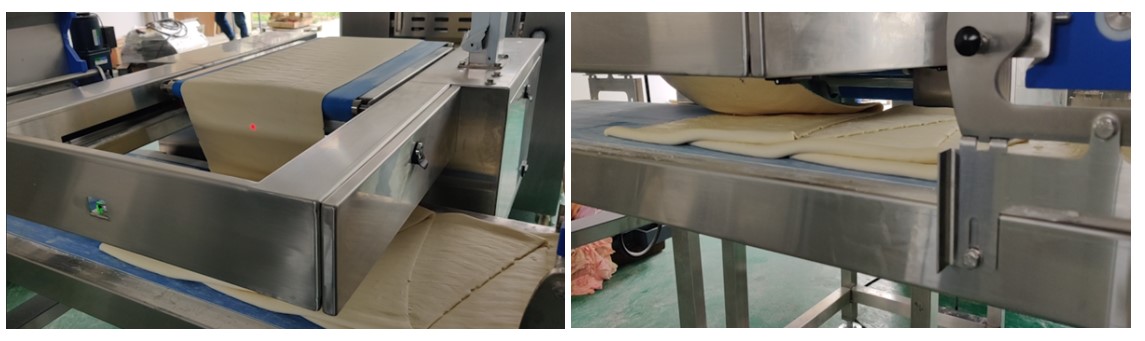

2) Hydraulic pressing system perfectly do pressing of dough ball into tortill skin.

3) Baking oven conveyor belt is made of teflon which prevent tortila skin from sticking on conveyor belt.

4) Running in a high automatization and intellectualization,no pollution.

This machine can produce : Chapati, Kulcha , Piadina , Tortilla , Roti, Pizza Base, Pita Bread,

2) Hydraulic pressing system perfectly do pressing of dough ball into tortill skin.

3) Baking oven conveyor belt is made of teflon which prevent tortila skin from sticking on conveyor belt.

4) Running in a high automatization and intellectualization,no pollution.

This machine can produce : Chapati, Kulcha , Piadina , Tortilla , Roti, Pizza Base, Pita Bread,

Main Parameters

Main ParametersFinal Product Show

Product Picture

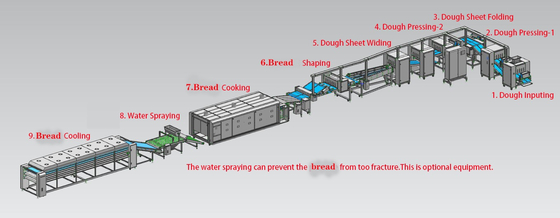

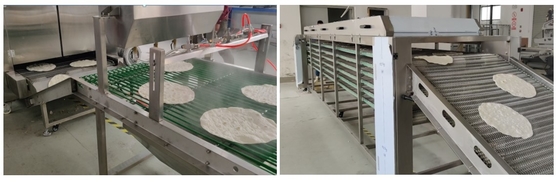

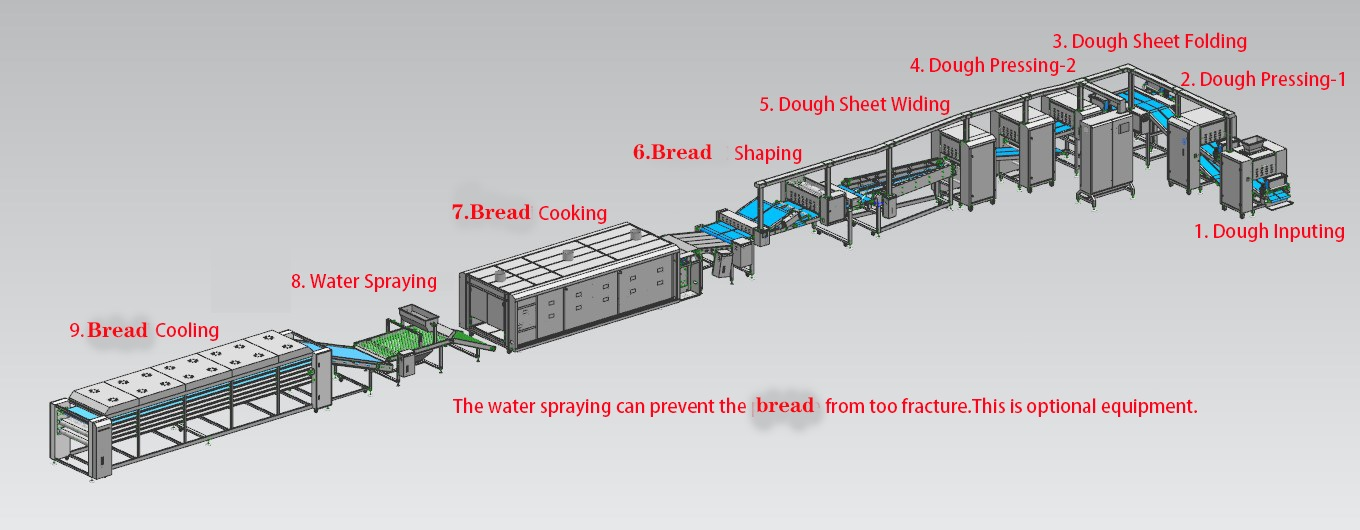

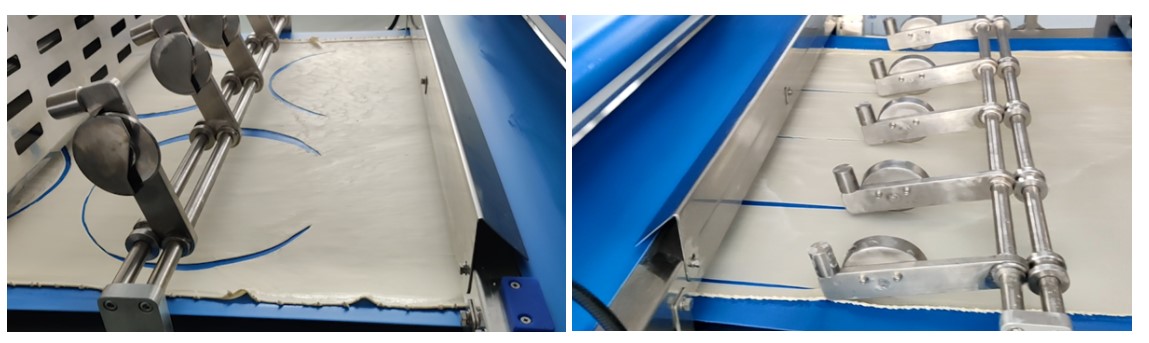

Product Picture1.After two rolling machine, the dough is thinned from thick.

2.Arrive to piling part,the dough is piled.

3.Next is horizontal rolling part,get out the space gap in pilling produce.After that,the dough sheet is pressed in two pressor to make it to become thinner and flatter.

4. The widor make the dough wider and thinner to prepare for next cuting step.

5.This machine can cut the dough into round or rectangle shape.the changing of knife can change the pancake shape.The round shape model has there type.

6.The rest of dough goes into the barrel to collect and second use.

7.Baking and cooling

Packaging & Shipment

Packaging & ShipmentRecommended Products