-

Tortilla Production Line

-

Fruit Processing Line

-

Fruit Puree Production Line

-

Fish Chili Sauce

-

Jam Paste Sauce Processing Line

-

Fruit Juice Production Line

-

Fruit Vegetable Processing Line

-

Color Sorter Machine

-

UHT Sterilizer Machine

-

Tomato Paste Processing Line

-

Mango Processing Line

-

Citrus Processing Plant

-

Commercial Tortilla Machine

-

Lavash Bread Maker Machine

-

Apple Processing Line

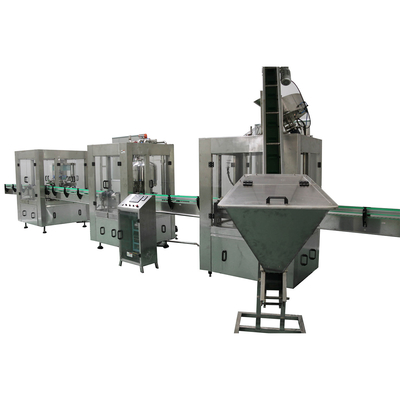

Alu Can Packing Energy Drink Production Line 250ml 33Ml 500ml

Contact me for free samples and coupons.

Whatsapp:0086 18588475571

Wechat: 0086 18588475571

Skype: sales10@aixton.com

If you have any concern, we provide 24-hour online help.

x| Item | 250ml 33-Ml 500ml Alu Can Packing Energy Drink Production Line | Input | Water & Sugar |

|---|---|---|---|

| Output | Energy Drink | Capacity | 2000can/h |

| Packing | Aluminum Can | Can Volume | 250ml, 330ml,500ml |

| Highlight | 250ml Drink Production Line,Alu Can Drink Production Line,30ml Drink Production Line |

||

250ml 33-Ml 500ml Alu Can Packing Energy Drink Production Line

process flow for Energy Drink Production Line

![]()

| 1 | High Shear Tank |

Ø Capacity: 100L Ø Double-layer thermal insulation structure, inner wall 3mm, middle 50mm polyurethane foam, outsourcing 1.5mm Ø High-speed shearing head, speed 2900R/min Ø Tank accessories: temperature gauge, positive and negative pressure safety valve, pressure gauge, breathable cap, CIP interface, pure water interface, inlet and outlet interface, liquid level sensor structure, etc. |

| 2 | Centrifugal pump |

Ø Flow: 1T/h Ø Material: SUS304 Ø Inlet and outlet connection: clamp connection, food grade plastic seal Ø Power: 2.2kw |

| 3 | Duplex filter |

Ø Water flow: 0.5T/H Ø 304 stainless steel material Ø Filter bag structure, filter precision can be replaced |

| 4 | Mixing tank |

Ø Capacity: 500L Ø Inner tank thickness: 3mm (SUS304); Ø Center paddle stirring; the outer surface adopts wire drawing board; Ø High and low liquid level control; conical head structure, including manhole, breathable cap, cleaning ball, water inlet, material inlet and outlet |

| 5 | Centrifugal pump |

Ø Flow: 1T/h Ø Material: SUS304 Ø Inlet and outlet connection: clamp connection, food grade plastic seal Ø Power: 2.2kw |

| 6 | Duplex filter |

Ø Water flow: 0.5T/H Ø 304 stainless steel material Ø Filter bag structure, filter precision can be replaced |

| 7 | Hot water system |

Ø Capacity: 1000L Ø Double-layer thermal insulation structure, the inner wall is 3mm, the middle insulation is 50mm, and the outer wall is 1.5mm Ø Tank accessories: temperature gauge, positive and negative pressure safety valve, pressure gauge, breathable cap, CIP interface, pure water interface, inlet and outlet interface, liquid level sensor structure, etc. Ø Reducing valve, regulating valve, float trap; Ø Domestic temperature sensor; Ø A set of automatic temperature control system; Ø Domestic high-quality steam shut-off valve, filter, etc., Ø Flow rate 3T/H Ø Lift 24 meters Ø Plate heat exchanger area 4M2 |

| 8 | Control cabinet |

Ø button control Ø Schneider or Omron Low Voltage Appliances Ø The cabinet is made of SUS304 stainless steel; Ø AirTAC Pneumatic Components |

Company Profile

Anhui Sanaisi Machinery Technology Co., Ltd.. is a leading supplier of food processing equipment in China.We are able to provide complete turnkey project solution for intelligent processing equipment.We are mainly specialized in fruit and vegetables processing line for puree,juice,jam,dried fruit, powder,fruit wine & vinegar,fermented beverage,ect And dairy production line.Also the related stand-along equipment with superior quality,competitive price and professional service.SSS has a complete team from R&D design, production, quality inspection,process guidance, with more than 20 years’ professional experience in this field.

![]()

![]()