-

Tortilla Production Line

-

Fruit Processing Line

-

Fruit Puree Production Line

-

Fish Chili Sauce

-

Jam Paste Sauce Processing Line

-

Fruit Juice Production Line

-

Fruit Vegetable Processing Line

-

Color Sorter Machine

-

UHT Sterilizer Machine

-

Tomato Paste Processing Line

-

Mango Processing Line

-

Citrus Processing Plant

-

Commercial Tortilla Machine

-

Lavash Bread Maker Machine

-

Apple Processing Line

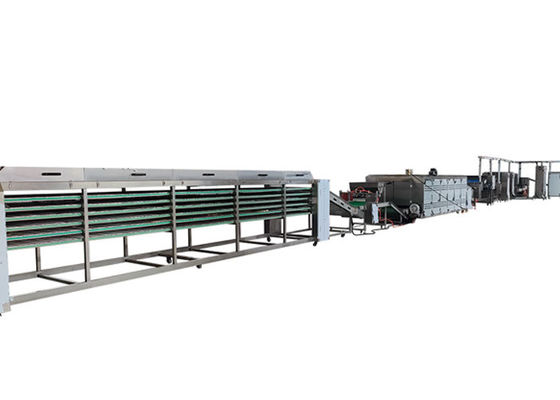

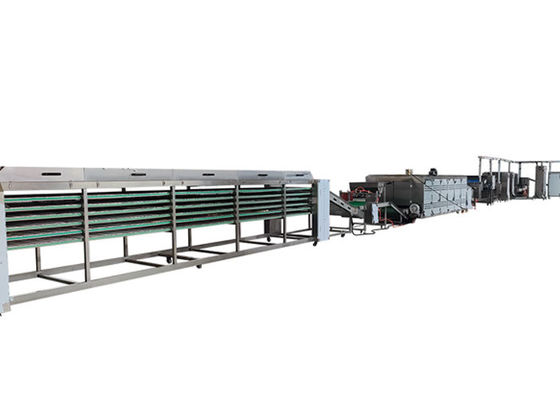

2000pcs/h Sanitary Stainess Steel Roti Making Equipment

| Condition | New | Colour | Silver |

|---|---|---|---|

| Thoughput | 2000-6000/hour | Voltage | 380v |

| Power | 21KW | Weight | 4800kg |

| Warranty | 1year | Dimension(L*W*H) | 17000*1200*1800mm |

| Highlight | Sanitary Roti Making Equipment,Stainess Steel Roti Making Equipment,2000pcs/h Roti Maker Machine |

||

Professional custom production torilla roti making machine

1. EQUIPMENT FOR FORMING TORTILLA

The dough loaded into the bunker of the divider is pumped by the augers into the head of the divider, where a steel string separates the portions of the dough. The design provides uniform feeding, which allows achieving high accuracy and stability of the weight of the separated portions.

Formation of dough pieces of a given thickness and diameter is performed by an automatic tortilla press with heating. The design and dimensions of the press make it possible to obtain tortilla blanks with high dimensional and shape accuracy.

| Material | 304 Stainlesss Steel |

| Warranty | 1 Year |

| Power | 21kw |

| Machine Weight | 4800kg |

| Advantage | Fully automatic |

2. EQUIPMENT FOR FORMING TORTILLA

The dough loaded into the bunker of the divider is pumped by the augers into the head of the divider, where a steel string separates the portions of the dough. The design provides uniform feeding, which allows achieving high accuracy and stability of the weight of the separated portions.

Formation of dough pieces of a given thickness and diameter is performed by an automatic tortilla press with heating. The design and dimensions of the press make it possible to obtain tortilla blanks with high dimensional and shape accuracy.

3. TORTILLA COOLING EQUIPMENT

After baking, finished products are cooled on conveyors. The number of tiers, the size and location of the conveyors are determined individually, depending on the available production space.

4. EQUIPMENT FOR GROUPING TORTILLA

The tortilla cooled to the temperature of packaging is served on a packing table or conveyor.

For the convenience of packaging, you can install a special two-row stacker, which groups the tortilla into two stacks with subsequent automatic feeding to packaging. The counting and adjustment of the number of products in the stacks is programmed individually.

Company Profile

Over the past 10 years, we have become a long-term supplier for many food companies and helped many food plants establish their production lines. Based on superior quality, competitive price and the best service, wc have gained great approval from customers.

Today SSS FOOD MACHINERY TECHNOLOGY CO.. LTD. will continuously stick to the core principle of 'Sincerity. Service and Success"and offer the best equipment for customers by virtue of keeping researching and developing. We are genuinely looking forward to cooperating with you and create a bright future with your good company together.

![]()