-

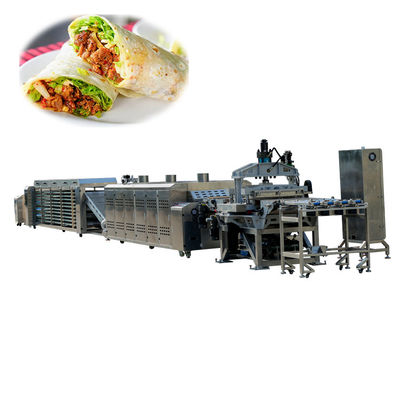

Tortilla Production Line

-

Fruit Processing Line

-

Fruit Puree Production Line

-

Fish Chili Sauce

-

Jam Paste Sauce Processing Line

-

Fruit Juice Production Line

-

Fruit Vegetable Processing Line

-

Color Sorter Machine

-

UHT Sterilizer Machine

-

Tomato Paste Processing Line

-

Mango Processing Line

-

Citrus Processing Plant

-

Commercial Tortilla Machine

-

Lavash Bread Maker Machine

-

Apple Processing Line

3800pcs/h Industrial Tortilla Maker Machine

Contact me for free samples and coupons.

Whatsapp:0086 18588475571

Wechat: 0086 18588475571

Skype: sales10@aixton.com

If you have any concern, we provide 24-hour online help.

x| Usage | Tortilla Making | Power | 43 Kw |

|---|---|---|---|

| Dimension | 26000x2030x1915mm | Gas Injiection | 4-14 M³/h |

| Thickness Of Pancake | Min 0.5mm | Material | 304 Stainless Steel |

| Advantage | Fully Automatic And High Efficiency | Function | Tortilla Production Line |

| Highlight | 3800pcs/h Industrial Tortilla Maker Machine,150mm Industrial Tortilla Maker Machine,High Capacity Tortilla Processinog Equipment |

||

Fully Automatic Tortilla Production Line Easy to Operate Tortilla Making

1. Description

Constituent parts of each machine in tortilla production line:

1. The roller consists of first rolling component, second rolling component, third rolling component, rolling mechanism, and conveying mechanism.

2. The dough divider is composed of knife assembly, conveying mechanism and dividing device.

3. The conveying table is composed of conveying mechanism.

4. The press machine consists of upper and lower heating plates, hydraulic mechanism, high temperature conveyor belt and conveyor chain.

5. The oven consists of electric heating tube, chain plate, and conveyor chain.

6. The cooling conveyor consists of cooling chain, conveying motor, and cooling fan.

7. The counter stacker consists of photoelectric counting mechanism, conveying mechanism and pneumatic device.

2. Technical Paramters

|

Model |

SSS-BP-60 |

| Capacity | 2000-3800 pcs/hour |

| Power | 42.57kw |

| Dimension | 26000 x 2030 x 1915(mm) |

| Diameter of product | ≤ 270mm |

| Gas consumption | 4-14m³ /hour |

3. Layout

![]()

4. Final Product