-

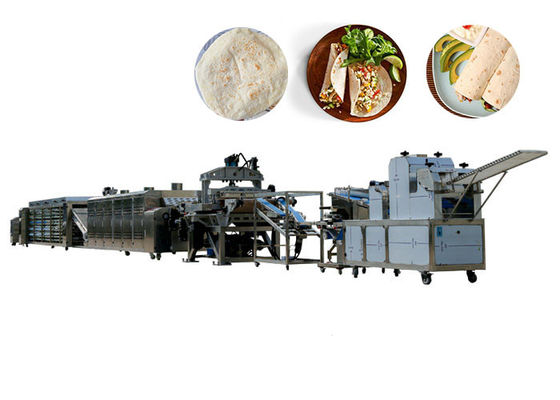

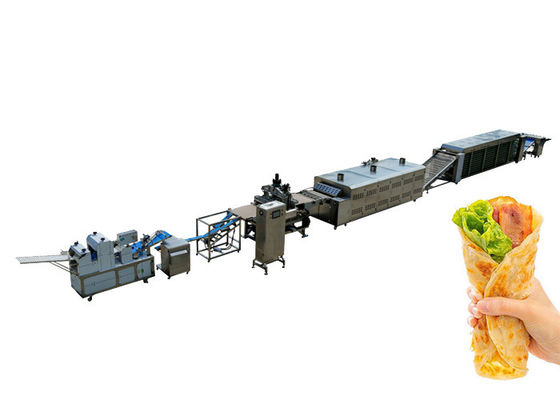

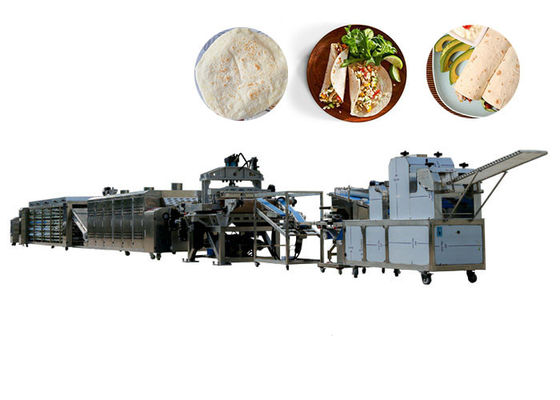

Tortilla Production Line

-

Fruit Processing Line

-

Fruit Puree Production Line

-

Fish Chili Sauce

-

Jam Paste Sauce Processing Line

-

Fruit Juice Production Line

-

Fruit Vegetable Processing Line

-

Color Sorter Machine

-

UHT Sterilizer Machine

-

Tomato Paste Processing Line

-

Mango Processing Line

-

Citrus Processing Plant

-

Commercial Tortilla Machine

-

Lavash Bread Maker Machine

-

Apple Processing Line

Max350mm 3800pcs/H Adjustable Roti Making Machine Automatic

Contact me for free samples and coupons.

Whatsapp:0086 18588475571

Wechat: 0086 18588475571

Skype: sales10@aixton.com

If you have any concern, we provide 24-hour online help.

x| Usage | Tortilla/Roti/Chapati Making | Power | 43 Kw |

|---|---|---|---|

| Dimension | 26000x2030x1915mm | Gas Injiection | 4-14 M³/h |

| Thickness Of Pancake | Min 0.2mm | Material | 304 Stainless Steel |

| Advantage | Fully Automatic And High Efficiency | Function | Tortilla Production Line |

| Highlight | 350mm Roti Making Machine,3800pcs/H Roti Making Machine,Adjustable Roti Making Machine |

||

Max350mm 3800pcs/H Adjustable Commercial Roti Making Machine

Automatic Tortilla Production Line Stainless Steel

1. Description

1. This Automatic Roti Making Machine has funny energy, safe production, no corner waste. Thickness and diameter can be adjusted, so that the roti produced in the appearance, taste, weight to achieve a unified space, which completely changed the current low production efficiency, waste of staff, the status of the middle of the crack.

2. The Automatic Roti Making Machine maker is made of stainless steel which is food grade materials, reasonable structure, maintenance, disassembly and cleaning is simple and convenient. Automatically send the skin, dusting, molding, skinning.

3. The Automatic Roti Making Machine is compact in structure, novel in appearance, beautiful in appearance, clean and sanitary. The shapes are neat and uniform.

2. Technical Paramters

|

Model |

SSS-BP-60 |

| Capacity | 2000-3800 pcs/hour |

| Power | 42.57kw |

| Dimension | 26000 x 2030 x 1915(mm) |

| Diameter of product | ≤ 270mm |

| Gas consumption | 4-14m³ /hour |

3.Overview

1) Dough ball automatically transfer to hydraulic heating formingchamber by conveyor

2) Hydraulic pressing system perfectly do pressing of dough ball intotortilla skin.

3)Baking oven conveyor belt is made of teflonnn which prevent tortillaskin from sticking on conveyor belt.

4) Running in a high automatization and intellectualization, nopollution.

4. Layout

![]()

5. Final Product