-

Tortilla Production Line

-

Fruit Processing Line

-

Fruit Puree Production Line

-

Fish Chili Sauce

-

Jam Paste Sauce Processing Line

-

Fruit Juice Production Line

-

Fruit Vegetable Processing Line

-

Color Sorter Machine

-

UHT Sterilizer Machine

-

Tomato Paste Processing Line

-

Mango Processing Line

-

Citrus Processing Plant

-

Commercial Tortilla Machine

-

Lavash Bread Maker Machine

-

Apple Processing Line

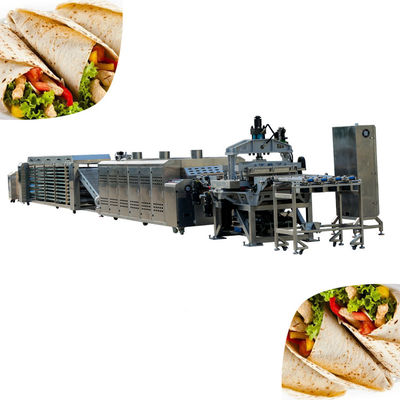

8inch Flat Bread 3600pcs Per Hour Tortilla Production Line Stainless Steel 304

Contact me for free samples and coupons.

Whatsapp:0086 18588475571

Wechat: 0086 18588475571

Skype: sales10@aixton.com

If you have any concern, we provide 24-hour online help.

x| Product Name | 8inch Flat Bread 3600pcs Per Hour Tortilla Production Line | Material | Stainless Steel 304 |

|---|---|---|---|

| Capacity | 2000-3600pcs/hour | Weight Of Tortilla | 50-55g |

| Power | 55kw | Dia Of Tortilla | 100-250mm |

| Gas Consuption | 4-14m³/ Hour | ||

| Highlight | 8inch Tortilla Production Line,3600pcs/Hour Tortilla Production Line,Stainless Steel 304 Tortilla Production Line |

||

8inch Flat Bread 3600pcs Per Hour Tortilla Production Line

1. Layout & process flow

![]()

After the dough is taken out from the dough mixer, it is divided into dough by the dough divider, and then sent to the proofing room for proofing. After proofing is completed, the dough is put on the conveyor and transported to the cake press to be pressed to the required size,then conveyed by the conveyor net to the oven for baking on both sides, and then conveyed by the stainless steel conveyor net to the cooling rack for cooling, and finally conveyed to the counting platform to realize the stacking of cakes and facilitate the final packaging.

2. Main feature & parameter

1. Humanized design and compact structure;

2. Microcomputer control, convenient operation;

3. Wide range of applications, and can make products of different sizes;

4. Flexible collocation, can be freely customized according to customer needs;

5. It is safe and reliable, and food contact parts are made of high-quality stainless

steel and food-grade polymer materials.

| Model | SSS-BP-60 |

| Processing capacity | 2000 - 3600 pcs / hour |

| Diameter | 100-250mm |

| Weight of tortilla | 50-55g |

| Total running power | 55kw |

| dimension | 10080*17100*1450mm |

| Diameter of product | ≤270mm |

| Gas consumption |

4-14m³/ hour |

3. Structure

The main operating steps of this machine are: dough segmentation, cake pressing,

baking, cooling, and cake stacking.

When the machine is working, put the dough and the dough into the dough divider

→ proofing → put the dough to Conveyor → cake pressing → baking → cooling →

counting stacks of cakes.

4.1 Divider and rounder

The principle of the dough divider is to divide and knead the dough into the required shape, size and weight.

4.2Transfer Conveyor

It can convey 2 - 4 rows dough ball with adjustable distance.

4.3 Flour press

Different tortilla sizes directly affect the upper limit of production capacity.

Size of press heating plate: 65x65cm

4.4 Oven

three layers in total.

Each layer of heating chain plate is equipped with 4 sets of gas heating system

4.5 Cooling conveyor

5-layer cooling system, each layer can individually control the conveying speed, the top is

equipped with cooling fan.

4.6 Stacker

Multiple

cylinders are combined with the detection and counting system to control the numberof stacked

tortillas, the stacked quantity can be adjusted.