-

Tortilla Production Line

-

Fruit Processing Line

-

Fruit Puree Production Line

-

Fish Chili Sauce

-

Jam Paste Sauce Processing Line

-

Fruit Juice Production Line

-

Fruit Vegetable Processing Line

-

Color Sorter Machine

-

UHT Sterilizer Machine

-

Tomato Paste Processing Line

-

Mango Processing Line

-

Citrus Processing Plant

-

Commercial Tortilla Machine

-

Lavash Bread Maker Machine

-

Apple Processing Line

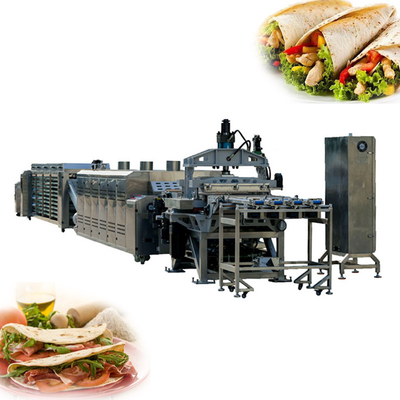

Middle Size Automatic Tortilla Production Line 2000 - 3600 Pcs/Hour

Contact me for free samples and coupons.

Whatsapp:0086 18588475571

Wechat: 0086 18588475571

Skype: sales10@aixton.com

If you have any concern, we provide 24-hour online help.

x| Machine Name | Mexican Tortilla Making Machine | Core Components | PLC, Engine, Motor, PTFE (Polytetrafluoroethylene)Belt |

|---|---|---|---|

| Warranty Of Core Components | 1 Year | Machine Material | 304 Stainless Steel |

| Belt Material | PTFE Polytetrafluoroethylene | Machine Color | Silver |

| Application Fields | Bakery; Food And Beverage Industry | Brand | SSS |

| Raw Material | Wheat Or Corn Floour | Marketing Type | Hot Sale 2021 |

| Highlight | 3600 Pcs/Hour Automatic Tortilla Production Line,Middle Size Automatic Tortilla Production Line,2000 Pcs/Hour Mexican Tortilla Making Machine |

||

Middle Size 2000-3600 Pcs/Hour Automatic Tortilla Production Line Manufacturer

Product Description

Since tortilla is a kind of popular food in both domestic and overseas, our tortilla making machines are becoming more and more popular. Here are the advantages of our machines:

1. The professional machine for making flour tortillas,especially design for wheat and corn flour.

2. The tortilla thickness is adjustable, the shape and size both support customization

3. Non-sticky, No waste, High efficiency, Energy saving, Safe production

4. Low noise, Automatic, Light weight, Easy to operate

It also adopts PLC and touch screen memory function, the original with the international famous brand, to ensure stable and stable performance, convenient maintenance.

| 720 Tortilla Production Line | |||

|---|---|---|---|

| Size of the line | 20640X2030X1915 MM(LXWXH) | ||

| Heating Method | Natural Gas or PL gas | ||

| Gas Consumption | 4-14 m³/h | ||

| Weight | 4500kg | ||

| Capacity | 3600 pcs / H | ||

| Power | 38.78KW | ||

| Max air pressure of the presser | 12MPA | ||

| Control System | Siemens | ||

| Electrical components | Chint, Schneider | ||

| Cable | Renmin | ||

| Display screen | Siemens | ||

![]()

![]()

![]()

Packing and Delivery:

![]()

First Step:

The heavy and bulky machinery and equipment are basically shipped by sea. Natural moisture and sealing are very important. Of course, shockproof is also very important. In order to prevent moisture, it is necessary to wrap several layers of plastic film on all equipment, and then wrap a layer of air bubbles to prevent collision and shock.

Second Step:

Use a wooden box (or wooden frame) to fix the equipment in the cabinet, and the size should be appropriate, so that it will not shake or tip over during transportation, and this requires professional carpentry to complete.

Our customers

![]()

![]()

Our Service

1. Pre-sales service:

Sales person, project manager, technology engineer, accountant staff

Professional responsing-team: would be very fast and exactly to send your offers

2. Online/sale service

Super and solid quality

Fast delivery

Standard export package or as your demand

3. After-sales service

Assistance to build factory

Repairing and maintenance if any problem occur in warranty

Installation and clerks training

Spare and wearing parts for free or with big discount

Any feedback of machines can be told us, and we will try our best to support

Our Company

Our service ranges from design and manufacture to sale as well as consultation. We are mainly specialized in bread processing equipment, fish processing equipment, vegetable & fruit processing equipment etc.

Our senior engineers have more than 20 years' professional experience in the field. Taking advantage of advanced technology and innovative design conception as well as rich experience in food processing machinery, we have been providing the highest level equipment for customers from all over the world. Our main markets are Russia, UK, USA, Brazil, New Zealand, Southeast Asia, Australia and so on.

Over the past years, we have become a long-term supplier for many food companies and helped many fish and food plants establish their production lines. Based on superior quality, competitive price and the best service, we have gained great approval from customers.