-

Tortilla Production Line

-

Fruit Processing Line

-

Fruit Puree Production Line

-

Fish Chili Sauce

-

Jam Paste Sauce Processing Line

-

Fruit Juice Production Line

-

Fruit Vegetable Processing Line

-

Color Sorter Machine

-

UHT Sterilizer Machine

-

Tomato Paste Processing Line

-

Mango Processing Line

-

Citrus Processing Plant

-

Commercial Tortilla Machine

-

Lavash Bread Maker Machine

-

Apple Processing Line

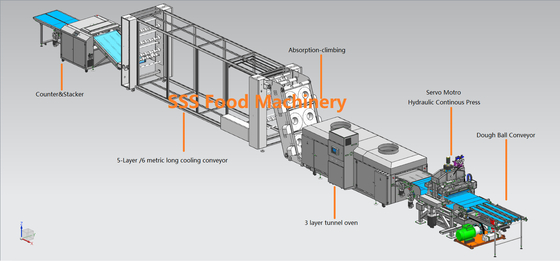

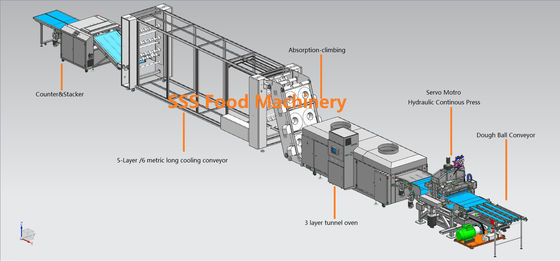

1000 - 7000 Pieces/h Automatic Tortilla Maker 0-300C Temperature Control Range

| Roller Speed | 3-20m/min | Roller Diameter | 8-50cm |

|---|---|---|---|

| Production Capacity | 1000-7000 Pieces/h | Roller Surface Treatment | Chrome Plating |

| Material | Stainless Steel | Roller Material | Alloy Steel |

| Roller Width | 8-50mm | Voltage | 220V/380V |

| Highlight | Stainless Steel Automatic Tortilla Production Line,PLC Automatic Tortilla Production Line,Tortilla Maker 7000 Pieces/H |

||

Product Description:

The Tortilla Production Line is a high-efficiency equipment for producing Pita/TORTILLA. With a production capacity of 1000-7000 pieces per hour, this equipment is the ideal choice for large-scale production. The roller is made of alloy steel, with a width range of 8-50mm and speed range of 3-20m/min. The Tortilla Line can also be customized for different production requirements. Thanks to its reliable performance and precise control, it has become one of the most popular Tortilla Production Equipment in the market, suitable for the large-scale manufacturing of Flour Tortilla Machine and Tortilla Making Machine.

Features:

- Tortilla Line: Tortilla Production Line

- Temperature Control Range: 0-300℃

- Roller Diameter: 8-50cm

- Roller Speed: 3-20m/min

- Production Capacity: 1000-7000 Pieces/h

- Roller Surface Treatment: Chrome Plating

Technical Parameters:

| Parameter | Value |

|---|---|

| Product Name | Pita/TORTILLA Production Line |

| Voltage | 220V/380V |

| Roller Material | Alloy Steel |

| Roller Surface Treatment | Chrome Plating |

| Temperature Control Range | 0-300℃ |

| Material | Stainless Steel |

| Production Capacity | 1000-7000 Pieces/h |

| Control System | PLC |

| Roller Speed | 3-20m/min |

| Roller Diameter | 8-50cm |

Applications:

The SSS brand pita production line from China is the perfect solution for producing delicious, high-quality pita bread. This tortilla production line is certified by CE and a minimum order quantity of 1 set. It comes with a competitive price range of 8000 to 120000 USD per set and is delivered within 25 days. Payment terms are through TT, and the supply capacity is 30 sets/month. The temperature control range is between 0 and 300℃ and the production capacity is between 1000 and 7000 pieces per hour. The control system is PLC and the roller diameter is between 8 and 50 cm, with a roller speed of 3-20 m/min.

Customization:

- Brand Name: SSS brand in china

- Model Number: tortilla production line

- Place of Origin: CHINA

- Certification: CE

- Minimum Order Quantity: 1

- Price: 8000-120000USD/set

- Packaging Details: wooden case

- Delivery Time: 25

- Payment Terms: TT

- Supply Ability: 30 sets/month

- Roller Width: 8-50mm

- Roller Speed: 3-20m/min

- Control System: PLC

- Product Name: Pita/TORTILLA Production Line

- Roller Material: Alloy Steel

SSS brand Tortilla Production Line is the perfect choice for making tortilla, pita, chapati and other flatbread. With CE certification, the Tortilla Maker is reliable and durable. It is controlled by PLC system and the roller material is alloy steel. The roller width and speed can be adjustable, ranging from 8-50mm and 3-20m/min. The minimum order quantity is one set and the price ranges from 80000-120000USD. The delivery time is 25 days and the payment terms is TT. The packing details is wooden case and the supply ability is 30 sets/month.

Support and Services:

Tortilla Production Line Technical Support and Service:

- Provide technical support for customers in the selection of equipment

- Provide technical training to help customers better understand and use the equipment

- Provide technical advice on the production process

- Regularly inspect and maintain the equipment

- Provide spare parts and accessories for the equipment

- Provide online remote technical support

- Provide solutions to customer problems in a timely manner

Packing and Shipping:

Tortilla Production Line Packaging and Shipping:

- Packaging: After the tortillas are produced, they are put into individual packages, such as plastic bags or cardboard boxes, and sealed for protection.

- Shipping: The packaged tortillas are then shipped to their destination, such as a grocery store, restaurant, or other food service provider.