-

Tortilla Production Line

-

Fruit Processing Line

-

Fruit Puree Production Line

-

Fish Chili Sauce

-

Jam Paste Sauce Processing Line

-

Fruit Juice Production Line

-

Fruit Vegetable Processing Line

-

Color Sorter Machine

-

UHT Sterilizer Machine

-

Tomato Paste Processing Line

-

Mango Processing Line

-

Citrus Processing Plant

-

Commercial Tortilla Machine

-

Lavash Bread Maker Machine

-

Apple Processing Line

Stainless Steel Dough Rounder For Tortilla Bread Production Line 220V/380V 3000-18000 Pieces/h For Production

| Voltage | 220V/380V | Dough Accuracy | ±2 Gram |

|---|---|---|---|

| Control System | PLC | Dough Weight | 28-130 Gram |

| Material | Stainless Steel | Production Capacity | 3000-18000 Pieces/h |

| Product Name | Dough Divider & Rounder | ||

| Highlight | Tortilla Bread Production Line Dough Rounder,380V Dough Rounder,3000-18000 Pieces/h Dough Rounder |

||

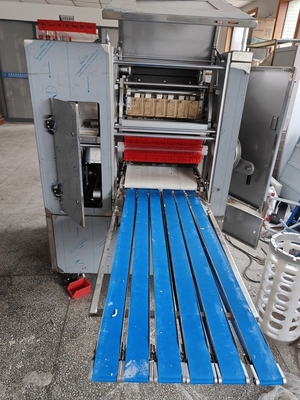

Dough Rounder Divider High Capacity

![]()

The dough making machine is capable of producing dough with a weight range of 28-130 grams. The dough balls making machine is designed to create perfectly round and uniform dough balls with an accuracy of ±2 grams. The tortilla baking machine is equipped with a PLC control system, ensuring precision in temperature control and cooking time.

The entire production line is designed to produce 3000-18000 pieces of tortilla per hour, making it ideal for large-scale production. The machine's high production capacity ensures that the production process is efficient and cost-effective.

Features:

The equipment is made of stainless steel, aluminum alloy and food-grade special materials. These materials provide high strength, corrosion resistance, safety and harmlessness to the produced food.

The equipment is suitable for medium to hard dough that has a moisture content of 50-65% (calculated based on the weight of flour).

The dough produced by the equipment provides high weight accuracy (±2g).

The equipment is especially suitable for mass production of baked goods. Some examples of the baked goods that can be made are frozen dough, hamburger pastry, hot dog pastry, tortilla pasta, small meal packs, and more.

The equipment is simple to operate and easy to clean daily. The failure rate is extremely low, making it an efficient and reliable tool in every kitchen.

Technical Parameters:

| Model | SSS-FT-9 | SSS-FT-6 | SSS-FT-4 | SSS-FT-6-2 |

|---|---|---|---|---|

| Dimension(L*W*H) | 2200*1300*1850 | 2200*1150*1800 | 2200*1000*1800 | 2200*850*1800 |

| Voltage (V) | 380V/50HZ | 380V/50HZ | 380V/50HZ | 380V/50HZ |

| Power (KW) | 7.5 | 7.5 | 5.5 | 5.5 |

| Hydraulic Pressure (KPa) | 30-40 | 30-40 | 30-40 | 30-40 |

| Max Capacity (PCS/H) | 18000 | 16000 | 8000 | 3000 |

| Dough Weight (G) | 40-70 | 28-130 | ||

| Accuracy (G) | ±2 | ±2 | ±2 | ±2 |

Applications:

With its high-quality stainless steel construction.The machine is also CE certified, ensuring that it meets the highest standards of safety and quality. The minimum order quantity for this product is one, and the price ranges from 8000-120000USD/set.

The packaging details include a sturdy wooden case to protect the machine during shipping. The delivery time is 25 days, and the payment terms are TT.

One of the key features of the Production Line is its dough accuracy. The machine is capable of producing dough with an accuracy of ±2 grams, ensuring that each tortilla is consistent in size and texture. The control system is also PLC, which allows for precise control over the production process.

Whether you are looking to make large quantities of tortillas for commercial purposes, or you simply want to create fresh tortillas at home, the Tortilla Production Line is an excellent choice. With its high-quality construction, precise control system, and versatile applications, this machine is sure to be a valuable addition to any kitchen or production line.

Order your Tortilla Production Line today and experience the convenience and efficiency of this innovative machine!

Support and Services:

- 24/7 phone and email support

- On-site installation and training

- Remote equipment monitoring and troubleshooting

- Regular maintenance and equipment upgrades

Our team of experienced technicians and engineers are dedicated to providing prompt and reliable support to minimize downtime and maximize productivity. Contact us for more information on our technical support and services.