-

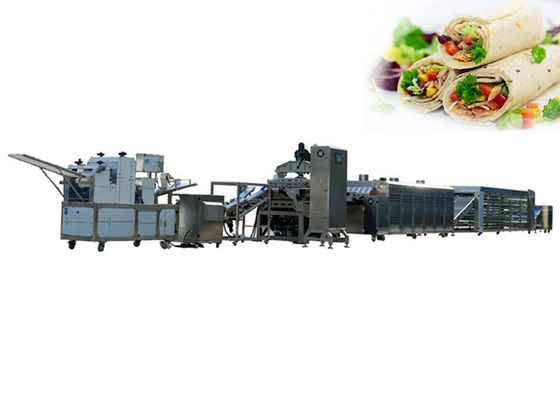

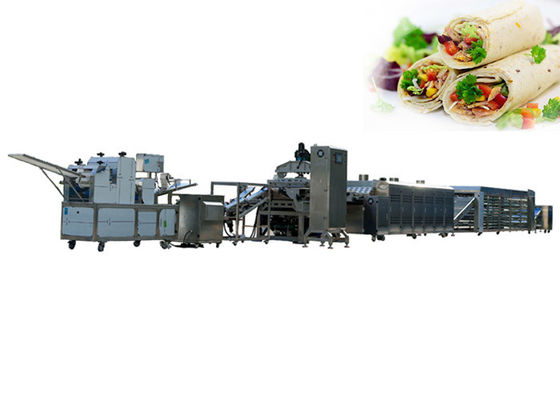

Tortilla Production Line

-

Fruit Processing Line

-

Fruit Puree Production Line

-

Fish Chili Sauce

-

Jam Paste Sauce Processing Line

-

Fruit Juice Production Line

-

Fruit Vegetable Processing Line

-

Color Sorter Machine

-

UHT Sterilizer Machine

-

Tomato Paste Processing Line

-

Mango Processing Line

-

Citrus Processing Plant

-

Commercial Tortilla Machine

-

Lavash Bread Maker Machine

-

Apple Processing Line

Fully Automatic Tortilla Production Line / Dough Making With Delta Control System

| Control System | Delta | Heating Method | Natural Gas Or PL Gas |

|---|---|---|---|

| Fuction | Tortilla Production Line | Power | 42kw |

| Gas Condumption | 4-14 M³/h | Size Of The Line | 21080*2120*2080mm |

| Export Countries | Global | Key Selling Points | High Productivity, Automatic, Easy Operation |

| Highlight | Delta Control System Tortilla Production Line,Fully Automatic Tortilla Production Line,Dough Making Tortilla Production Line |

||

| Diameter of the product | 6-12 inches | |

|---|---|---|

| Capacity | 2000-8000 pcs/hr | |

| Size of the line | 21080*2120*2080mm | |

| Weight | 4500kg | |

| Power | 42kw | |

| Gas consumption | 4-14 m³/hr | |

| Pressure range of the presser | 0.3MPA-14MPA | |

| Heating method | Natural gas or PL gas |

Product Description:

The Tortilla Making Machine is designed with a weight of 4500kg, making it sturdy and durable for long-term use. The machine is equipped with a Delta control system, which ensures precise and accurate control of the production process, resulting in consistent tortilla quality every time.

The Model BP-720 is a highly efficient and reliable machine that is capable of producing a maximum of 720 tortillas per hour. The machine is designed with a dough divider rounder, which helps in the accurate division of dough, and a dough balls making machine that forms the dough into perfect balls.

The Tortilla Production Line is designed to meet the demands of the food industry, providing a reliable and efficient solution for businesses involved in the production of tortillas. The machine is capable of producing tortillas in a range of sizes and thicknesses, making it a versatile addition to any production line.

The presser of the machine has a pressure range of 0.3MPA-14MPA, ensuring that the tortillas are produced with the right amount of pressure for the perfect consistency and texture. The machine is also easy to operate, with a user-friendly interface that makes it easy for operators to adjust settings and monitor the production process.

In conclusion, the Tortilla Production Line is a must-have for any business involved in the production of tortillas. With its high efficiency, reliability, and versatility, the machine is an excellent investment that will help businesses increase their output and streamline their production processes. Whether you're running a bakery, a restaurant, or any other type of food business, the Tortilla Production Line is the perfect choice for all your tortilla production needs.

Technical Parameters:

| Display screen: | Delta |

| Function: | Tortilla Production Line |

| Export Countries: | Global |

| Gas Consumption: | 4-14 M³/h |

| Production Capacity: | 2000-8000 Pieces/h |

| Power: | 42kw |

| Control System: | Delta |

| Electrical Components: | Chint, Schneider |

| Diameter of Tortilla: | 6-10 Inches |

| Size of the Line: | 21080*2120*2080mm |

Applications:

The Tortilla Production Line is suitable for various occasions and scenarios such as bakeries, restaurants, food processing factories, and large-scale tortilla production. The machine's high productivity ensures that it is ideal for mass production of tortillas, making it perfect for commercial use. The machine's automatic system also makes it easy to operate, reducing the need for highly skilled labor. The Tortilla Production Line can produce up to 2000 tortillas per hour, making it a highly efficient machine.

The Tortilla Production Line is CE certified, ensuring that it meets European quality standards. The machine has a minimum order quantity of 1 and a price range of 8500-11000USD per set. The machine comes packaged in a wooden case and has a delivery time of 25 days. Payment terms include TT and L/C, and the machine's supply ability is 1 set for 1 month. The machine's size is 21080*2120*2080mm, making it compact and easy to fit in most production areas.

The Tortilla Production Line's core components are the motor and PLC, which ensure that the machine runs smoothly and efficiently. The machine's control system is Delta, which is known for its reliability and ease of use. The key selling points of the Tortilla Production Line are its high productivity, automatic system, and easy operation. These features make it a highly sought-after machine in the bread production industry.

Customization:

Product Customization Services for the Tortilla Production Line:

- Brand Name: SSS brand in China

- Model Number: Tortilla Production Line

- Place of Origin: China

- Certification: CE

- Minimum Order Quantity: 1

- Price: 8500-11000USD/set

- Packaging Details: wooden case

- Delivery Time: 25 days

- Payment Terms: TT , L/C

- Supply Ability: 1 set for 1 month

- Material: 304 Stainless Steel

- Function: Tortilla Production Line

- Key Selling Points: High Productivity, Automatic, Easy Operation

- Weight: 4500kg

Product Attributes:

- Dough rounder

- Tortilla Making Machine

- Bread Production Equipment

Support and Services:

Our Tortilla Production Line is designed to provide efficient and reliable production of high-quality tortillas. We offer comprehensive technical support and services to ensure that our customers can maximize the performance and lifespan of their production line.

Our technical support team is available to answer any questions and provide guidance on installation, operation, and maintenance. We also offer training programs for operators and maintenance personnel to ensure that they are equipped with the knowledge and skills to operate and maintain the production line effectively.

In addition, we offer a range of services to help our customers optimize their production processes and improve product quality. These services include process optimization, recipe development, and product testing.

Our goal is to provide our customers with the support and services they need to achieve their production goals and maximize their return on investment.

Packing and Shipping:

Packing:This machine is packed with film before packing into plywood box, and box is stable and firm enough to adapt all kinds of transportation.

Shipping:we will ship the machine as per customers' request including by sea, by air, by truck, by train, etc.

![]()

FAQ:

1) Are you a manufacturer / factory?

Yes, we are a real factory / manufacturer with more than 10 years of experience.

2) Where are you located? Can we visit your factory in China?

Oh sure. Welcome to us. Our factory is located in Anhui City, China (Mainland).

3) What is the Warranty and Installation Procedure of the Machine?

We offer instruction manual in English, installation and video management. Overseas technician is available. Full 1 year machine warranty, lifetime maintenance and support.

4) What is the min order quantity?

Our moq is 1 unit, and we can provide you with discount if more units are ordered.

7) Can I change the motor as my local voltage?

We can change the voltage as your requirement, and there's no extra charge.

8) How do your control quality?

We have an inspection team to check the products at all stages of the manufacturing process.

5) what's the packing of the machine?

In wooden pallet, In plastic film, the spare parts and cabinet packed by wooden box.

6)What's the payment term?

Usually by T/T ( 30% in advance, the balance against the copy of B/L),or L/C at sight.

9) What documents do you offer for customs clearance?

As a rule, we offer an original Commercial invoice, sales contract, packing list, if you have any

need. Some special documents are needed, you can discuss with us before ordering, we will try our best to service.

Welcome to contact lena for more details.