-

Tortilla Production Line

-

Fruit Processing Line

-

Fruit Puree Production Line

-

Fish Chili Sauce

-

Jam Paste Sauce Processing Line

-

Fruit Juice Production Line

-

Fruit Vegetable Processing Line

-

Color Sorter Machine

-

UHT Sterilizer Machine

-

Tomato Paste Processing Line

-

Mango Processing Line

-

Citrus Processing Plant

-

Commercial Tortilla Machine

-

Lavash Bread Maker Machine

-

Apple Processing Line

Mango Fruit Pulp Production Line With Aseptic Big Bag Package

Contact me for free samples and coupons.

Whatsapp:0086 18588475571

Wechat: 0086 18588475571

Skype: sales10@aixton.com

If you have any concern, we provide 24-hour online help.

x| Item | Mango Fruit Pulp Production Line With Aseptic Big Bag Package | Input | Raw Mango |

|---|---|---|---|

| Output | Mango Pulp | Capacity | 1-100t/h As Required |

| Package | Aseptic Bag | Feature | Turnket Project Solution |

| Highlight | Mango Fruit Pulp Production Line |

||

Mango Fruit Pulp Production Line With Aseptic Big Bag Package

![]()

3. specification for main parts

|

item |

Brand/origin |

| PLC, HMI | Siemens/Germany |

| Low voltage electric component | Schneider/France |

| Pneumatic element(air cylinder, solenoid valve, triple) | Air TAC/Taiwan |

| Flow meter |

Krohne/Germany E+H/Switzerland |

| valve | Liyang Sifang/China |

| Motor | Fangli/China |

| pump | Nanfang/China |

| Thickness of ss tube |

1.5mm for small diameter(1.25”,1.5”,2”) 2.0mm for big diameter(>2”) |

| Stainless steel material | 304 from top mill in China(Baosteel, Tisco) |

| Double mashing machine with platform |

Ø Horizontal structure with dual workstations; Ø Suitable for processing various crushed fruits and vegetables in pulp Ø Mesh diameter Φ 0.8mm- Φ 1.2mm, one set each, used to remove the skin from the jam, while refining the product to make its particles small and uniform; Ø The drive adopts dual motors; Ø The beating machine body is made of SUS304 stainless steel material, platform Ø 304 stainless steel pedestrian steps, Ø 304 material protective railings and handrails Ø anti slip corrugated surface, platform feet fixed on the ground; |

| Storage tank |

Ø 304 stainless steel material;thickness 3mm Ø Single-layer upper and lower cone-bottom structure; Ø With stirring Ø The outer surface adopts 2B sheet; Ø High and low liquid level control; Ø Conical top and cone bottom structure, including manhole, vent cap, cleaning ball, water inlet, material inlet and outlet, visual sight glass; Ø The inlet and outlet adopt anti-foam and anti-swirl structure; |

| screw pump |

Ø Food grade rubber stator; mechanical seal with thruster Ø Outlet flange connection; |

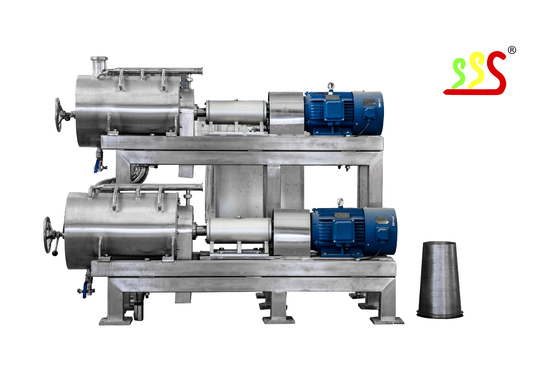

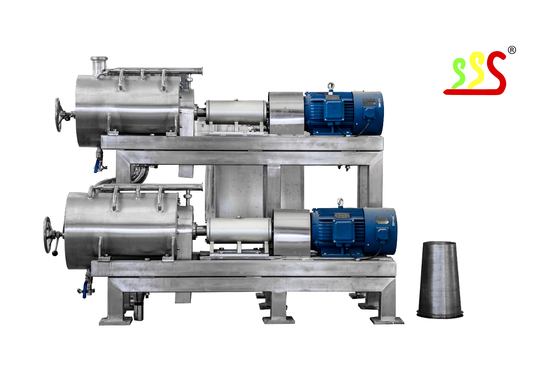

| UHT sterilizer |

Ø Tubular type Ø It is produced and manufactured by patented technology, which is the leading special sterilizer for high-viscosity materials in China. It is mainly composed of a heat exchanger, a continuously variable transmission pump, a retainer, a closed water bucket, a plate type superheated water heat exchanger, and a controller. The process of the equipment is as follows: Ø Material inlet temperature 40℃~50℃ Ø Material outlet temperature is less than 40℃ Ø Sterilization temperature 95℃~121℃ Ø Sterilization time 15S Ø Cooling water temperature <30℃ Ø One set of screw pump with adjustable speed Ø One CIP pump Ø Pre-material buffer tank with stirring Ø Superheated water heating plate, sealed water tank with sterilization pump Ø Steam valve group: globe valve, pressure reducing valve, regulating valve, steam trap, filter, etc. |